How to Measure and Identify Oil Seals?

Replacing a critical component like an oil seal can be challenging, especially without the original machine specifications. Fortunately, oil seals can be identified by their design, size, and material. With hundreds of options on the market, this guide focuses on the four most common designs. These seals typically come with either a single or double lip and are made from materials such as Nitrile or Viton rubber.

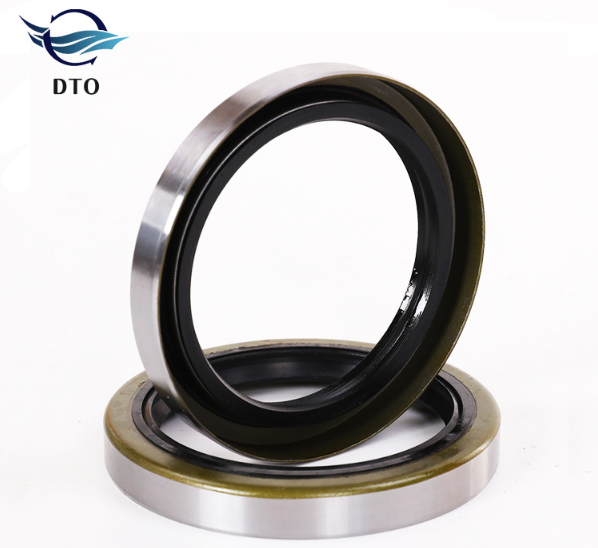

Understanding Double Lip Grease Seals

A double lip grease seal, as you might have guessed, has two sealing lips. The first lip acts like a single lip seal by keeping the lubricant in. The second lip adds an extra layer of protection, facing outward to block contaminants.

How Does a Double Lip Seal Work?

The additional lip in a double lip seal serves as a secondary barrier. While the inner lip retains the lubricant, the outer lip actively prevents external elements from entering the system. This design is especially useful in harsh environments where dirt, dust, or moisture could easily penetrate.

Common Applications of Double Lip Seals

Double lip seals are often found in more demanding applications. They are ideal for equipment that operates in harsh environments, such as outdoor machinery or automotive applications. They can withstand higher levels of contamination and provide longer-lasting protection.

Oil Seal Single Lip vs Double Lip

Firstly, the oil seals covered in this guide classify the single lip as the inner diameter at the bottom of the component. The single lip is vital to the function of the seal by containing the oil, grease or lubricant. The only difference between a single and double lip is the additional rubber lip on the top of the oil seal which helps prevent dust or dirt from coming close to the shaft.

Identifying an oil seal lip can be difficult through visual inspection alone. To check, press along the inner diameter at the top of the seal—if you feel a ridge with slight movement or flexibility, it's highly likely that you have a double-lipped oil seal.

Identifying Oil Seal Designs

1. Type A - Rubber Covered Lip Seals

Fully covered outer diameter for excellent sealing. This oil seal is entirely enclosed in rubber, making it the most commonly used type. It offers great resistance to thermal cycling, high temperatures, and various chemicals.

2. Type B - Metal Outer Diameter Oil Seals

An economical option with a metal outer diameter, ideal for standard applications. The exposed metal allows for a tighter fit between the seal and the housing or bore but has limited effectiveness in sealing thin liquids or gases.

3. Type C - Reinforced Metal Insert Oil Seals

Similar to Type B, but with an additional inner case for enhanced structural rigidity. This design is typically used in heavy-duty machinery or for larger diameter seals.

4. Type F - Stainless Steel Garter Spring Oil Seals

Based on the Type A design, but with a corrosion-resistant metal case and a stainless-steel garter spring. This type is suitable for a wide range of fuels and chemicals, offering added durability.

Final Thoughts

Choosing the right grease seal is crucial for ensuring the longevity and efficiency of your equipment. Whether you opt for a single lip or double lip grease seal, understanding the specific requirements of your machinery will help you make the best choice. And if you’re ever in doubt, it's always a good idea to consult with a supplier who can guide you through the options.

Contact Us for Expert Advice

Need help deciding which grease seal is right for your needs? Contact us today! Our team of experts can guide you through the selection process and provide recommendations based on your specific application. We work with leading suppliers to ensure you get high-quality seals tailored to your requirements.

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0